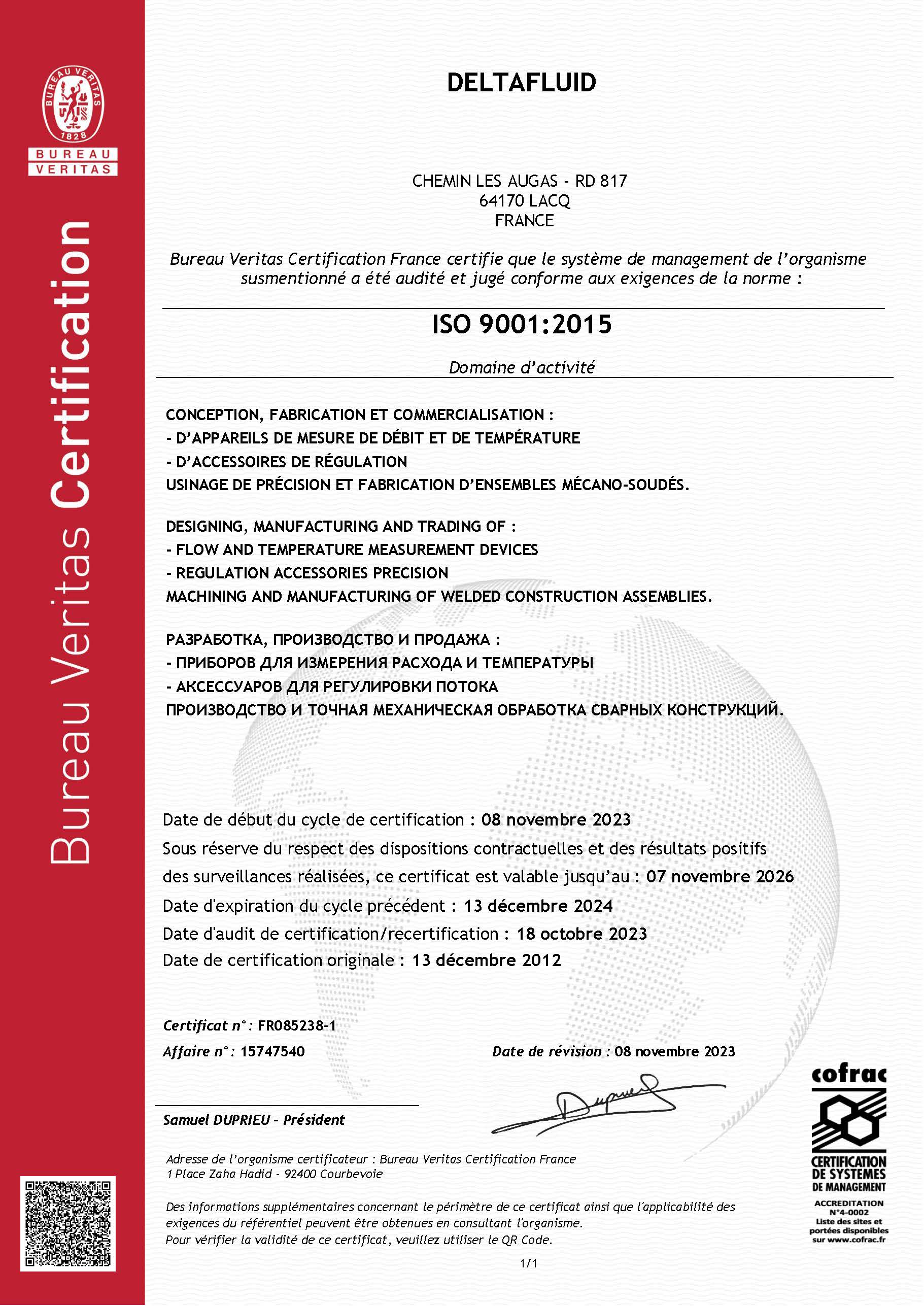

ISO 9001 certification

Deltafluid has been ISO 9001 certified since 2012. Control audits are regularly conducted to verify our compliance with this quality management system.

Beyond the procedural aspects of this certification, the fact of listing all the processes of the company from your quote request to the manufacturing of the products allows us to provide you with products and services of optimal quality. All Deltafluid's employees follow the same instructions, validated by our quality department and audited by the certification body.

A quality committee meets twice a month to adapt existing procedures, develop topics for continuous improvement, analyze any non-compliances and make proposals for preventive actions.

An increased demand for quality products ...

- an extensive range of products and solutions, designed by our design departments and manufactured in our workshops in France,

- products that comply with international industry standards and guidelines,

- a product warranty of 12 months from the date of installation or 18 months from the date of shipment to the customer,

- bi-monthly quality meetings to prevent any risk of non-compliance,

... and services.

- the respect of delivery times (90% of customers delivered on time),

- the satisfaction of all our customers (95% of satisfied customers surveyed),

- maintaining our ISO 9001: 2015 certification,

- a team at your service every day from Monday to Friday from 8:30 to 12:30 and from 13:30 to 17:30,

ISO 19443 certification

Since November 2023, Deltafluid has also been ISO 19443 certified. This certification, result of a long organizational and structural work, demontrates our desire and ability to work in the field of nuclear energy and to provide IPSN products & services (IPSN = Important Pour la Sûreté Nucléaire = Important for nuclear safety).

It also confirms our commitment which began in 2020 with our qualification by EDF-UTO in the field of piping accessories.

A responsibility for health, safety and the environment at work:

- an objective of zero work accidents by working on the training of machine operators, on safety measures and on protective equipment,

- periodic inspection of equipment (forklift, overhead cranes, etc.),

- specific labeling and procedure for the handling of dangerous products,

- an improvement of the waste sorting system,

- a reduction in energy consumption.

You can download here our ISO9001 & ISO19443 certificates.