Flow measurement with flange pressure tappings

The 1''/1'' flowmeter is also called a flowmeter with flange pressure taps.

The high pressure upstream measurement is 1 inch from the upstream edge of the plate and, symmetrically, the low pressure measurement is 1 inch from the downstream edge of the plate.

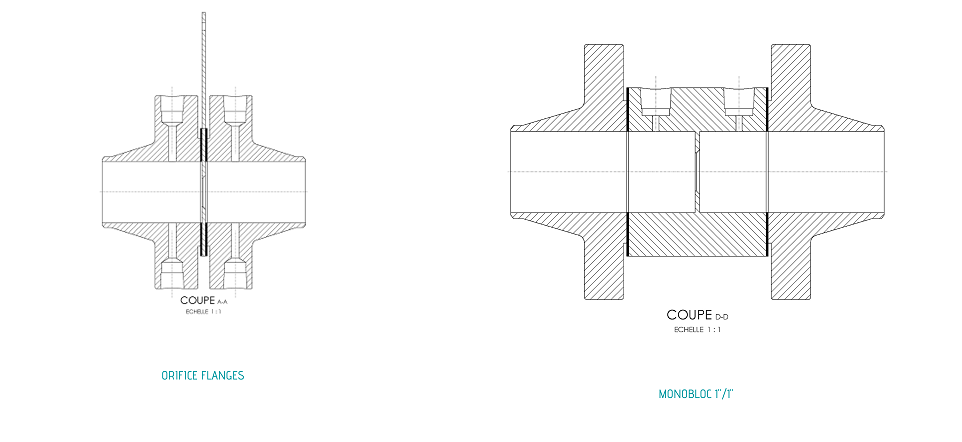

This is often a pre-assembled complete set with orifice plate mounted between orifice flanges.

Orifice flanges are standardized and manufactured to ASME B16.36. The orifice plate is manufactured in accordance with ISO 5167 or ASME MFC-3M.

The 1''/1'' flowmeter may include either a sharp edge, a conical, a quarter circle, an eccentric, a segmental or a conditioning orifice plate depending on your application and process specification Our experts advise you on the most suitable orifice plate.

A 1''/1'' flowmeter is a differential pressure flowmeter with pressure taps at the flange. Its characteristics depend on those of the measuring element considered, the orifice plate mounted between these flanges. For details on the features, refer to the orifice plate datasheet: either sharp edge, conical, quarter circle, eccentric, segmental or conditioning orifice plate.

The different 1''/1'' assemblies :

This system with pressure taps integrated into the flange (orifice flanges) is widely used for small diameters (up to about DN300). Beyond that, it becomes more economically interesting to use simple flanges with 0/0 or D - D/2 pressure taps. Refer to the datasheet of the considered primary element for the recommended pressure taps.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

The 1''/1'' pressure taps (1 inch is the distance between the pressure tap and orifice plate) or the flange pressure tap are often used for diameters up to DN300 . Indeed, it is necessary to mount the orifice plate between orifice flanges which are often more expensive than simple flanges. This price gap increases with the diameter of the flanges, so we will tend to limit their use.

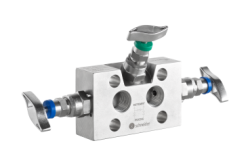

1''/1'' pressure taps are also available as a monoblock version. In this case, the assembly is more economical.

The D - D/2 pressure taps correspond to a high pressure tap located at 1D upstream of the plate and a low pressure tap located at 1/2D downstream of the plate. This type of pressure tap is used for large diameters often beyond DN150 (6 ''). The bosses for the pressure taps are made directly on the pipework, which makes it possible to use simple flat flanges for the mounting of the measuring element and to save money.

The long radius nozzle will always be used with D-D/2 pressure taps.

0/0 pressure taps or pressure taps in the corners allow:

- either in monoblock version 0/0, to have integrated pressure taps and to be able to use simple flanges for mounting the measuring element (or directly to weld it on the pipework for the monoblock version to be welded)

- either in annular chamber version, to mount the element between single flanges

In any case, it is necessary to refer to the product data sheet which stipulates the types of pressure taps authorized for each product.