Used to measure reference flow in calibration applications

GENERAL DATA

- Standards: ISO 9300, ASME PTC 19.5.

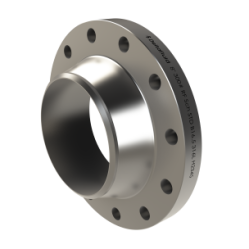

- Flange connection.

- Material: Standard: carbon steel, 304L / 316L stainless steel, others according to your application.

- Fluid: gas.

- Value of β <0.25 (β = d / D).

- Accuracy: 0.3% of max flow.

- Repeatability of the measurement: 0.1%.

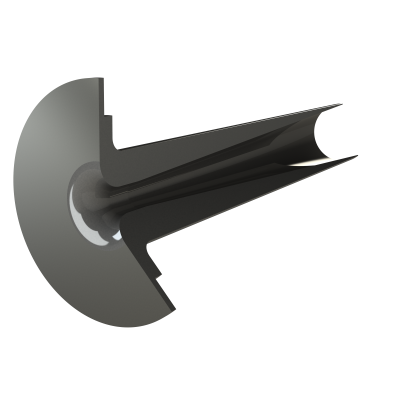

The sonic state of the nozzle means that the flow reaches the speed of sound when going through the throat. Under these conditions, the flow rate depends mainly on the upstream pressure and the fluid temperature. This makes it possible to deliver a stable and perfectly known flow, independent of the downstream pressure conditions of the nozzle. This nozzle is thus used to provide a standard flow value when it comes to calibrating another type of flow meter.

If you can not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

There are situations where flow meters need to provide very accurate and reliable value, this is the case when they are used for commercial transactions. For example, on a gas meter station, the data they report is the basis for billing gas quantities. Given the quantities transported, a small measurement error can have important consequences. Thus, to ensure correct counting, it is necessary to use a flow meter truly calibrated according to the intended conditions of use. The measuring instrument must therefore be compared to a standard to be able to verify its performance. This calibration must be carried out before commissioning and during periodic checks according to the regulations in force.

The nozzle in sonic mode (choked flow achieved) is then used to provide the standard value of flow. Indeed, under critical flow conditions, the flow depends only on the temperature and the pressure upstream of the measuring element. If the conditions upstream of the sonic nozzle can be kept constant, the flow will remain constant. This is the major interest of these measuring devices as a means of calibration.