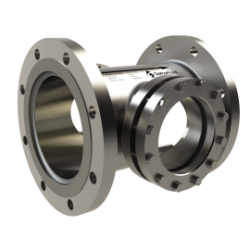

Multi-hole restriction orifice

Suitable for reducing noise when passing the orifice

GENERAL DATA

- Standards: Element based on R.W. MILLER or ISO 5167. Possible design following Idel'cik for holes with rouded or beveled edges.

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: all sizes.

- Orifices: dimensioned according to the fluid, the pressure drop or the flow to be achieved going through the restriction.

Orifices with rouded or beveled edges (according to Idel'cik) on demand.

- Plate thickness: calculated taking into account the pressure drop generated by the plate and the diameter of the pipework in order to avoid a deformation of the plate. NEED MORE DETAILS?

- Noise: the number of orifices is determined according to the level of noise not to be exceeded.

The maximum noise level depends on the operating conditions: limited to 85 dB(A) by the regulatory body for an average daily exposure in continuous operation.

Intermittent or emergency operation - acceptable upper values (see corresponding regulations).

If the noise level is still too high, it is possible to switch to a multi-stage restriction orifice.

HOW TO LIMIT THE NOISE LEVEL WHEN PASSING TRHOUG THE RESTRICTION?

- Cavitation: for liquids, the cavitation level is checked for each plate and the orifices are calculated to avoid cavitation.

LEARN MORE

- Critical regime (choked flow or choking cavitation): the orifices are calculated at the critical flow limit for a maximum pressure drop.

BETTER UNDERSTAND THE CRITICAL REGIME (choked flow for gases or choking cavitation for liquids) using a graph.

You can find below our most frequently asked questions / answers.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

In which case does a multi-hole restriction orifice is used?

The fluid passing a restriction is accelerated and this can cause an increase in sound level. Multiplying the number of holes in the plate can significantly reduce noise.

MORE DETAILS

Why choose Idel'cik type orifices?

The orifices of a pressure reducer are generally simpe and straight i.e. without bevel (unlike orifice plates for flow measurement).

To facilitate flow, the Idel'cik design offers orifices with rouded or beveled edges.