Quarter-circle orifice plate

Recommended for viscous fluids

GENERAL DATA

- Standard: ISO / TR 15377.

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 25 to 500 mm.

- Accuracy: 2% of max flow.

- Repeatability of the measurement: 0.1%.

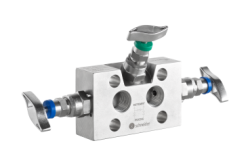

- Pressure taps: in the corners, at the flange.

| ISO/TR 15377 | ||

|---|---|---|

| ReD | Reynolds number in pipework | 250 ≤ ReD ≤ 6.104 |

| D | Pipe interior diameter | 25 mm ≤ D < 500 mm |

| d | Orifice diameter | d > 15 mm |

| β | d/D | 0,245 ≤ β ≤ 0,6 |

| Ra | Upstream face roughness | Ra < 10⁴.d |

| r | Quarter circle radius | 0,100.d ≤ r ≤ 0,207.d |

| e | Quarter circle hole thickness | 2,5 mm ≤ e ≤ 0,1.D |

| E | Plate thickness | E ≥ r |

| α | Downstream bevel angle if necessary | α = 45° |

| t | Flatness tolerance | Nous consulter |

You can find below our most frequently asked questions / answers.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

When to use a quarter circle orifice plate?

A quarter-circle orifice plate has a rounded entrance (a bit like a nozzle). It therefore accepts more or less dirty and aggressive fluids since its input radius does not deteriorate. However, for a very aggressive or corrosive fluid, we recommend to apply a resistant coating (deposit of stellite or ceramic projection).

Moreover, it accepts fluids with a low Reynolds number (up to 250) so it is suitable for the measurement of viscous fluids.

To understand and choose from the different orifice plates, refer to the selection table.