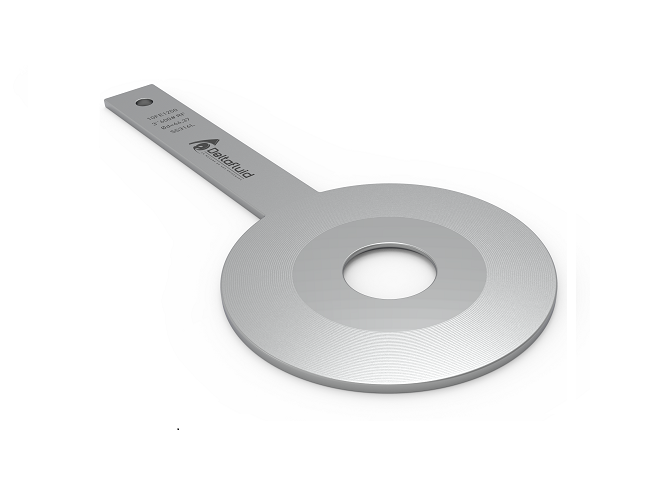

Sharp-edge orifice plate

Economical and reliable solution

GENERAL DATA

- Standards: ISO 5167-1 & 2, ASME MFC-3M, ISO / TR 15377.

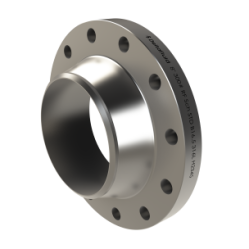

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 25 to 1000 mm.

- Accuracy: 0.5% of max flow.

- Repeatability of the measurement: 0.1%.

- Pressure taps: in the corners, at the flange or D-D / 2.

| ISO/TR 15377 | ISO 5167-1&2 | ASME MFC-3M | ||

|---|---|---|---|---|

| ReD | Reynolds number in pipework | 5 000 ≤ ReD ≤ 10⁸ | ||

| D | Pipe interior diameter | 25 mm ≤ D < 50 mm | 50 mm ≤ D ≤ 1 000 mm | |

| d | Orifice diameter | d ≥ 12,5 mm | ||

| β | d/D | 0,5 ≤ β ≤ 0,7 | 0,1 ≤ β ≤ 0,75 | |

| Ra | Upstream face roughness | Ra < 10⁴.d | ||

| r | Sharp edge radius | r < 0,0004.d | ||

| e | Orifice thickness | 0,005 d ≤ e ≤ 0,02.D | ||

| E | Plate thickness | e ≤ E ≤ 0,05.d | ||

| α | Upstream bevel angle | α = 45° ± 15° | ||

| t | Flatness tolerance | t < 0,005.(D-d)/2 | ||

You can find below our most frequently asked questions / answers.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

Why choose a sharp-edge orifice plate?

The sharp-edge orifice plate is the most common. It responds to a large number of applications and is generally used for clean fluids (gas, liquid or steam). It fits on pipes from 25 to 1000 mm.

You will find here a table that allows the selection of the primary elements of flow measurement.

What is the standard used for the design and manufacture of a sharp-edged orifice plate?