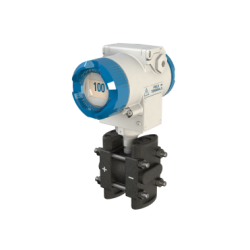

Suitable for large steam flows

GENERAL DATA

- Standards: ISO 5167-1 & 3, ASME MFC-3M.

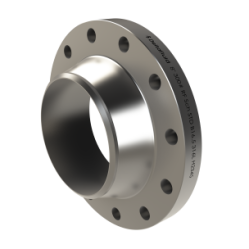

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation

- or solder connection (BW)

- Material: Standard: carbon steel, stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 50 to 500 mm.

- Accuracy: 2% of max flow.

- Repeatability of the measurement: 0.1%.

- Pressure points: D - D / 2.

| ISO 5167-1&3 & ASME MFC-3M | |||

|---|---|---|---|

| High ratio | Low ratio | ||

| ReD | Reynolds number in pipework | 104 ≤ ReD ≤ 107 | |

| D | Pipe interior diameter | 50 mm ≤ D ≤ 630 mm | |

| β | d/D | 0,25 ≤ β ≤ 0,8 | 0,2 ≤ β ≤ 0,5 |

| Ra | Upstream face and throat roughness | Ra < 10⁴.d | |

| bn | Length of the cylindrical throat | bn = 0,6.d | |

| a | Total length of the nozzle | a = D/2 + 0,6.d | a = d + 0,6.d |

| H | Thickness | 3 mm ≤ H ≤ 0,15.D | |

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

Both nozzles are standardized, the details of their characteristics are explained in the standards.

We can specify that, in general, an ISA1932 nozzle has an input plane perpendicular to the axis of the fluid, a convergent, a cylindrical throat and a possible bevel to avoid damaging the output edge. On a long radius nozzle, it is also possible to see a convergent portion and a cylindrical throat, but they have a different shape from the ones of the ISA1932 nozzle. In addition, the ISA1932 nozzle must be mounted with corner pressure taps (0/0) or an annular chamber while the long radius nozzle will have a D-D/2 pressure taps connection (D upstream and D / 2 downstream) of the inlet face of the nozzle). More over, the standard specifies that the uncertainty on the discharge coefficient of the ISA 1932 nozzle is 0.8% while it is 2% for the long radius nozzle.

Only a calculation integrating all the characteristics and the requirements of your process will allow us to guide you in your choice.

According to the standard, there are 2 types of long radius nozzles: one with a large opening ratio (0.25 ≤ β ≤ 0.8) and one with a small opening ratio (0.20 ≤ β ≤ 0.5) .

It is the profile and the length of the convergent inlet that differs between the two types of nozzles.

Only a calculation integrating all the characteristics and the requirements of your process will allow us to guide you in your choice.