Simple, economical and leak-free installation

GENERAL DATA

- Standards: ISO 5167-1 & 2, ASME MFC-3M or ISO / TR 15377.

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 306L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 25 to 600 mm (beyond, consult us).

- Overall measurement accuracy: 0.5% of max flow.

- Repeatability of the measure: 0.1%

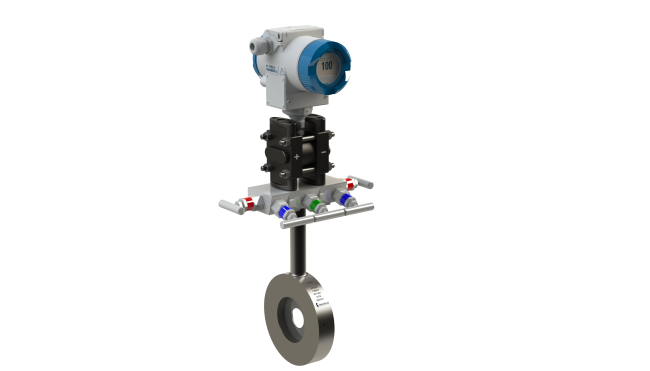

THE FLOWMETER INCLUDES:

- the desired orifice

- integrated compact pressure taps

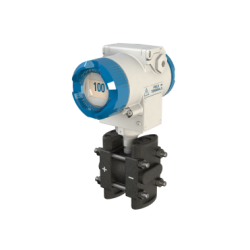

- integrated 3 or 5-way manifold or single plate

- the optional preset differential pressure transmitter

- the built-in temperature sensor (for temperature compensation) in option

MOUNTING AND ASSEMBLY DATA:

- Direct mounting of the differential pressure transmitter, no connecting tube

- Reduced installation and commissioning costs

- No risk of leakage: device factory-tested, no maintenance

CHARACTERISTICS :

- monoblock orifice plate - see corresponding technical data sheet

ACCESSORIES :

- temperature sensor - supply of a probe directly integrated in the compact flowmeter - see corresponding technical data sheet

- multivariable transmitter - this transmitter allows correction of the density of the gases according to the temperature and the pressure - see corresponding technical data sheet

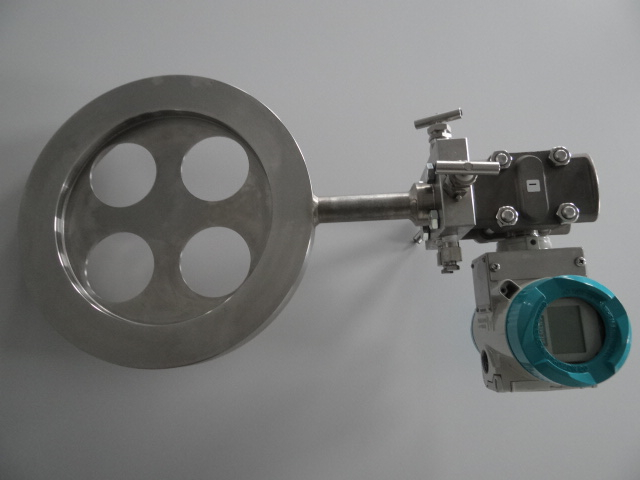

In all cases where the transmitter can be mounted close to the piping (no problem of space or temperature of the fluid) and for the measurement of liquid and gas (the steam requires condensation pots and thus independent impulse lines), the compact flowmeter is recommended. It offers a ready-to-install solution that eliminates the risk of impulse line leakage.

The costs associated with the installation and maintenance intervention are therefore considerably reduced.

The pressure taps are welded and 100% tested, inserted into a tube directly welded to the monoblock port on one side and to the manifold on the other. The differential pressure transmitter should be mounted directly on the manifold.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

This flowmeter is compact in that the pressure taps are integrated and are directly connected to the manifold and transmitter: no need to connect the pulse taps on the flanges or pull lines to connect to the transmitter (with the associated risk of leakage), simply mount the flowmeter in the pipe and adjust the transmitter for proper operation.

This compact assembly should be used with caution with a high temperature fluid due to the direct mounting of the differential pressure transmitter.

Advantages :

- connection tubes for impulse taps already connected and 100% tested

- no risk of leakage

- direct mounting in the pipework

- reduced installation and commissioning costs

Disadvantages:

- not suitable for all applications (high temperature fluids, remote display transmitter)