To rinse and clean a separator membrane

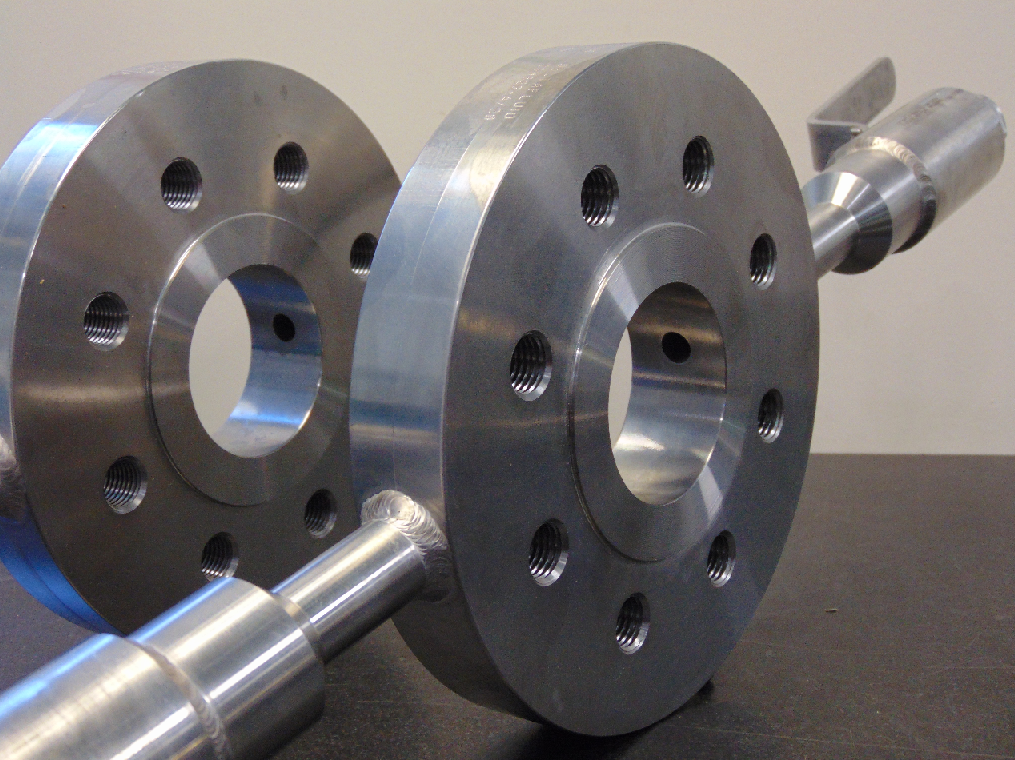

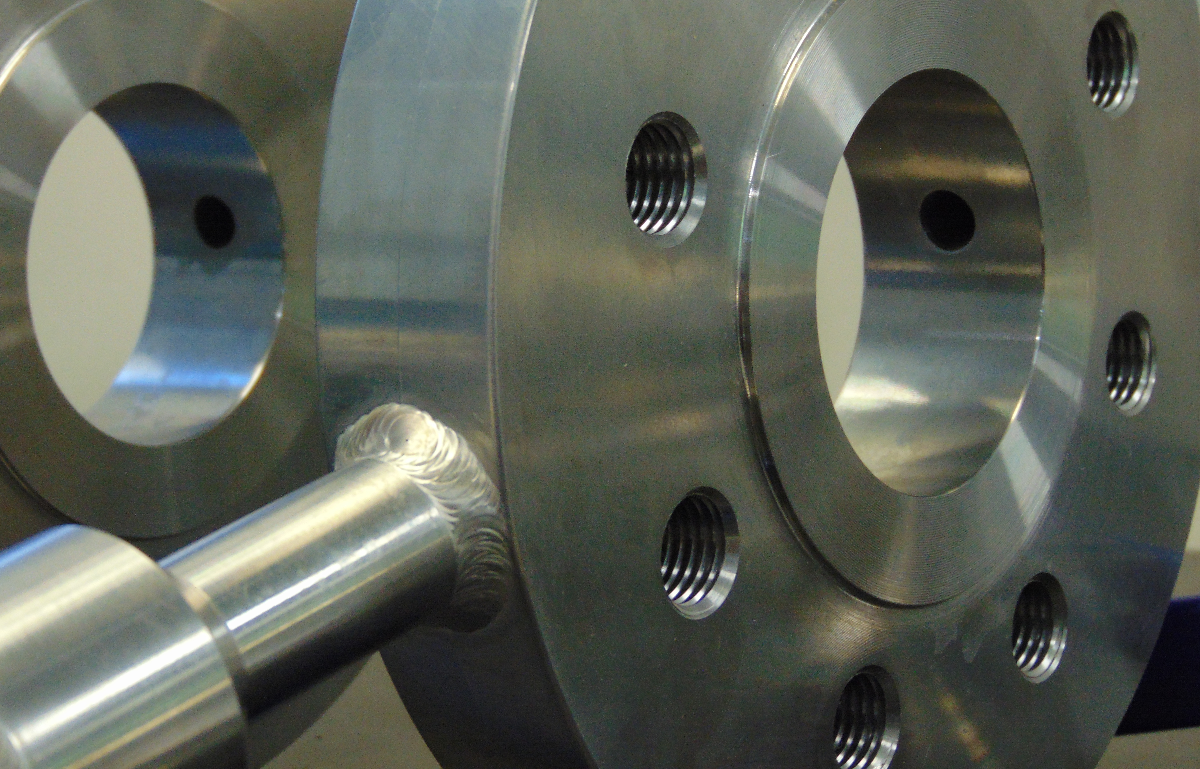

The flushing ring is an accessory intended to be mounted on the branch of a pipe upstream of a separator (connected to a pressure transmitter).

It offers the possibility of rinsing and cleaning the separator membrane if impurities are present - due to pitting (stagnation) or to the characteritics of the fluid to be measured. It thus allows reliable measurements of the process pressure.

It also helps for purge of the preocess and calibration of the transmitter.

- Materials : carbon steel, stainless steel, monel, hastelloy, inconel, duplex, super duplex, titanium, tantalum, PVC, PTFE...

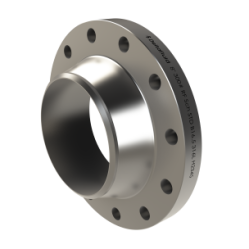

- Flange process connection (RF, RTJ or groove/tongue face)

- Maximum operating pressure: limited by the flange rating

- Nominal diameter: to be adapted according to the size of the connection

- Connection to the flushing outlets to be defined according to your application: screwed, welded, with flange, with nipples, with valves

- Optional plugs for flushing orifices

- Manufacturing compatible according to DIN, EN1092-1, EN1759-1, ASME B16.5, API flanges

- ...

The models are manufactured on request, contact us for more details.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

When measuring the pressure of particularly aggressive, abrasive, corrosive, adherent or toxic fluids, the measuring instrument, i.e. the pressure transmitter, must be protected. It is then mounted on a separator whose membrane allows the separation of the fluid to be measured.

The separator membrane being highly stressed by these aggressive fluids, it is then necessary to install a flushing ring so that it can be rinsed and cleaned easily.